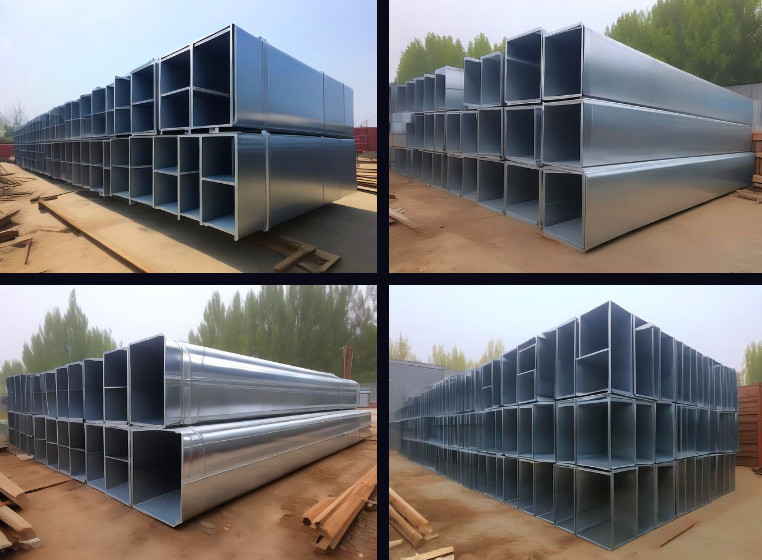

Common Square Tubes Used in Light Steel Villas

2024-09-23 14:58

Light steel villas are increasingly favored for their quick construction, environmental friendliness, and energy efficiency. In light steel structures, square tubes serve as a primary load-bearing material and play a crucial role. This article will delve into the common types, specifications, materials, and connection methods of square tubes used in light steel villas.

1. Common Types of Square Tubes

The main types of square tubes commonly used in light steel villas include:

1. Ordinary Square Tubes: The most common type, widely used in the framework of light steel villas, with specifications ranging from 20mm×20mm to 100mm×100mm, selected based on design and load requirements.

2. Thick-Walled Square Tubes: Typically used for load-bearing parts like columns and beams, they offer better compression and bending resistance, suitable for larger loads.

3. Galvanized Square Tubes: Commonly used to prevent corrosion, galvanized treatments effectively extend the lifespan of square tubes, especially in humid or corrosive environments.

2. Common Specifications of Square Tubes

The typical specifications for square tubes are as follows:

?20mm×20mm: Suitable for lightweight partitions and support structures.

?40mm×40mm: Commonly used for columns in light steel frames with moderate load-bearing capacity.

?50mm×50mm: Suitable for beams and most load-bearing structures.

?60mm×60mm and 80mm×80mm: Appropriate for critical structures requiring higher load-bearing capacity.

3. Material Selection

In light steel villas, square tubes are usually made from two low-alloy high-strength steels: Q235 and Q345. Q235 is suitable for standard load-bearing structures, while Q345 is used in areas with higher load requirements. The choice between them should be based on specific engineering needs and budget.

4. Connection Methods

The connection methods for square tubes are crucial for the overall stability and safety of the structure. The main methods include:

1. Welding: The most common method in light steel structures, providing strong connections, with attention needed on welding techniques and seam quality for reliability.

2. Bolt Connections: Easy to disassemble and maintain, suitable for flexible layouts in light steel villas. The strength can be adjusted by selecting appropriate bolt specifications.

3. Angle Steel Connections: In special cases, square tubes can be connected with angle steel to enhance structural stability.

5. Surface Treatment of Square Tubes

To improve corrosion resistance, hot-dip galvanizing or spraying treatments are commonly used. Hot-dip galvanizing forms a protective zinc layer to prevent oxidation, while spraying offers a variety of color options, enhancing aesthetics and providing some corrosion resistance.

6. Conclusion

The various types of square tubes used in light steel villas significantly impact the safety and durability of the buildings. Proper selection of tube types, specifications, and connection methods, along with scientific surface treatments, can effectively enhance the overall performance of light steel villas. I hope this information provides valuable insights; feel free to reach out with more questions!